Electric furnace

Purpose: Melting glass Customizable: Yes

Product Category:

Product Application

Product Details

Product Parameters

A type of glass melting furnace; after it was discovered that high-temperature glass can conduct electricity, electric energy can be used as a heat source to melt glass, that is, using an electric melting furnace to melt glass. Electric melting furnaces have gradually begun to partially replace flame furnaces.

Glass tank furnaces heated by flame on the surface have a long history. Although many structural improvements have been made during long-term use, there are still some serious drawbacks: such as low thermal efficiency, complex furnace structure, large volume, and harsh working environment.

In the late 1940s, electric melting furnaces were truly used for commercial production. From the perspective of usage effects, electric melting furnaces have prominent advantages, including high melting rate, simple structure, high degree of automation, and good working environment.

Its main principle is to use electric energy as the heat source. Generally, silicon carbide or molybdenum disilicide resistance heating elements are installed on the side walls of the furnace chamber for indirect resistance radiation heating. Some crucible furnaces used for melting special glass adopt induction heating, relying on eddy currents induced in the furnace and glass melt for heating. Tank furnaces directly use the glass melt inside the furnace as the heating resistor, with multiple groups and layers of electrodes arranged at different depths of the glass melt to generate heat, and temperature control is achieved by adjusting power consumption. When using this method, the temperature in the space above the glass melt surface is very low (called a cold furnace top), so energy is basically consumed in melting glass and heat dissipation through the furnace walls, with no heat loss carried away by flue gas or environmental pollution from exhaust gases. Thermal utilization is high, and there is no need to set up combustion or waste heat recovery systems. Electric furnaces can be automatically controlled, require fewer managers, and have good working conditions, but consume a large amount of electrical resources. They are suitable for melting refractory glass, volatile glass, and dark-colored glass. Large electric furnaces can produce up to 150 tons of bottle and container glass per day.

Keywords:

Related Products

FAQ

How to get a quote?

Hello, please provide detailed product model, specifications, quantity, for example AZS-33#-WS 250*400*1700 20 pieces, etc. If you have a material list, you can send it to the company's official email.

What is the quotation process?

Hello, contact us — online consultation.

Is your price a bulk price?

Hello, generally our quotation includes processing, assembly, and packaging.

Are you a factory or a middleman?

Hello, Far East Refractories is a refractory manufacturing company. Our users are spread all over the world. Asahi Glass, Almex, Swarovski, Xinyi Group, Qibin Group, Guangdong Huaxing, and others are our long-term partners, so you can purchase with confidence.

Customer Cases

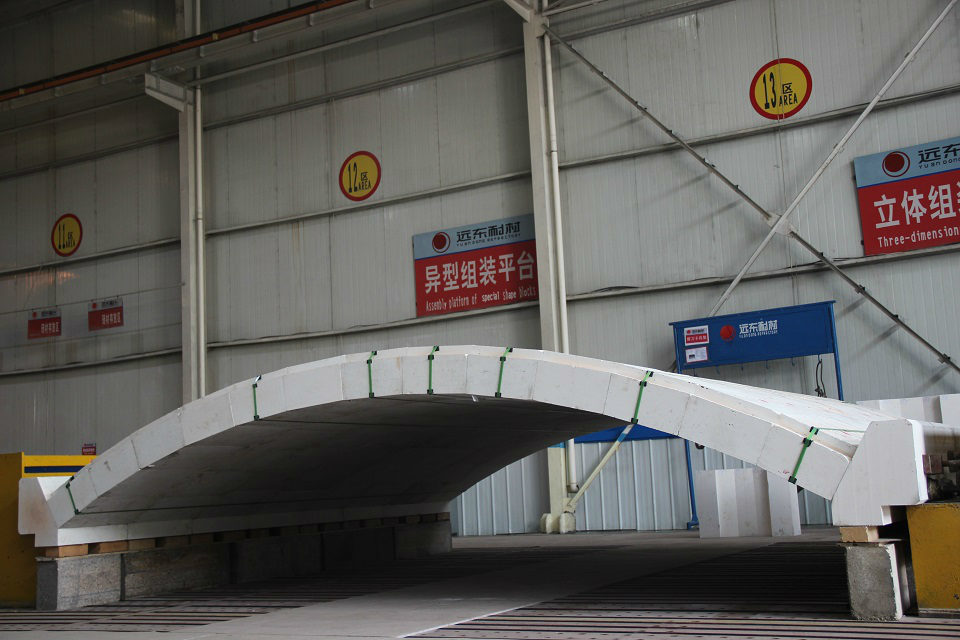

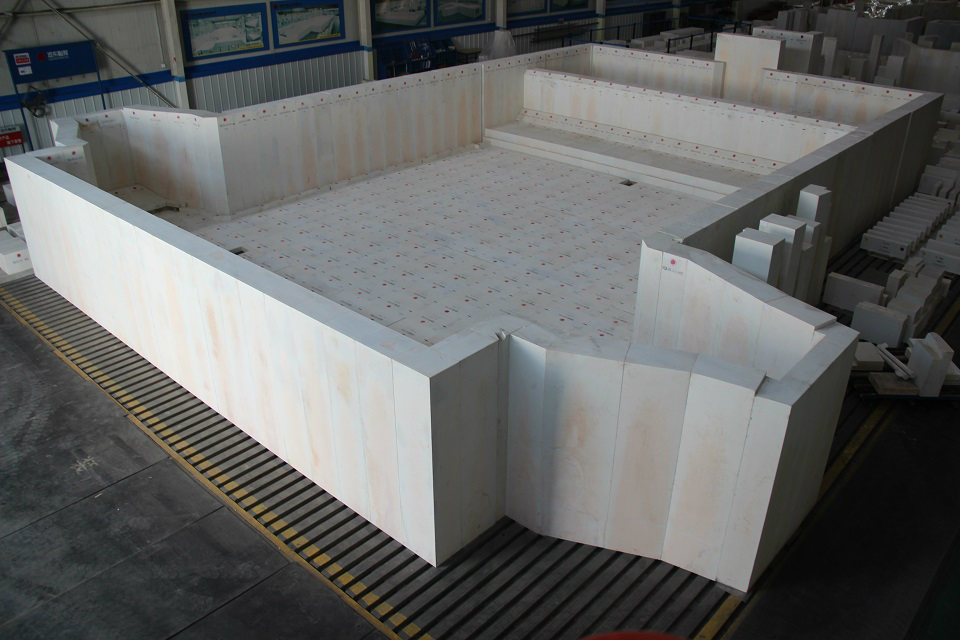

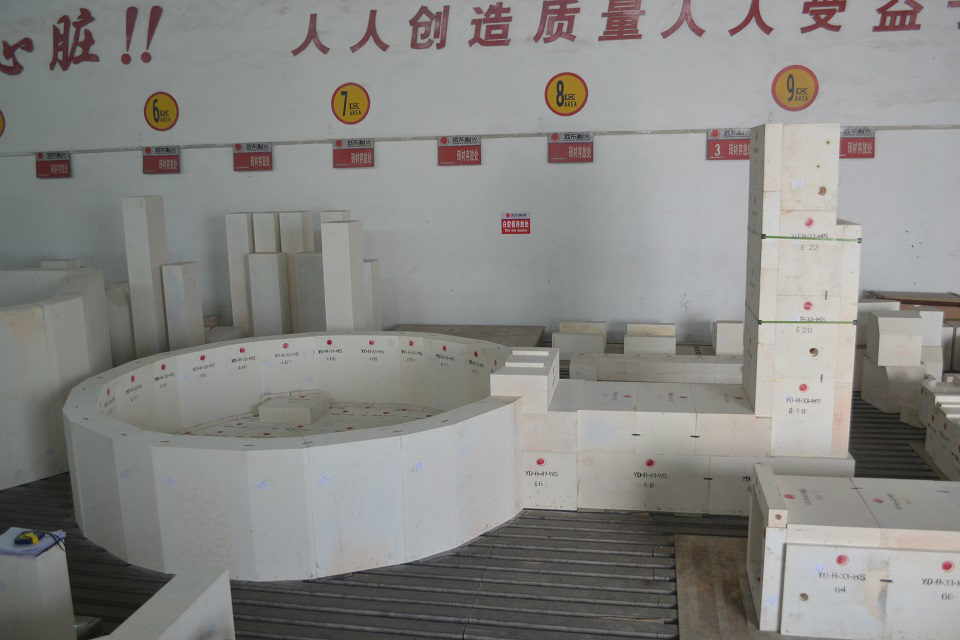

Full oxygen combustion kiln roof charging

Float Glass Furnace Space

Belgian Horseshoe Flame Glass Furnace

Shanghai Glass Electric Fusion Kiln

Online Consultation

Please leave your relevant requirements, we will contact you as soon as possible