αβ paving

This product is composed of 45% α-Al2O3, 53% β-Al2O3, and 2% glass phase. Because it does not contaminate the glass melt and has good resistance to glass corrosion and excellent high-temperature wear resistance at 1350°C, it is widely used in the refining section, cooling section, and working tank of glass furnaces.

Product Category:

Alpha Beta Series

Product Details

Product Introduction

This product is composed of 45% α-Al2O3, 53% β-Al2O3, and 2% glass phase. Because it does not contaminate the glass melt and has good resistance to glass corrosion and excellent high-temperature wear resistance at 1350℃, it is widely used in the refining section, cooling section, and working bath of glass furnaces.

Product Specifications

| Item | Specification | |

| Chemical Composition ( w )/% | Al2O3 | 93–96 |

| K2O+Na2O | 3.2–5.0 | |

| Fe2O3+TiO2+SiO2+CaO+Others | ≤2.0 | |

| Bulk Density (Dense Part) /(kg·m-3) | ≥3300 | |

| Compressive Strength at Room Temperature / MPa | ≥200 | |

| Load Softening Temperature / ℃ | ≥1700 | |

| Static Resistance to Glass Corrosion (Calcium Sodium Glass ≤1350℃ 48h) mm /24h | ≤0.4 | |

| Apparent Density (kg·m-3) | PT | ≥3050 |

| WS | ≥3250 | |

Keywords:

Products

Related Products

FAQ

How to get a quote?

Hello, please provide detailed product model, specifications, quantity, for example AZS-33#-WS 250*400*1700 20 pieces, etc. If you have a material list, you can send it to the company's official email.

What is the quotation process?

Hello, contact us — online consultation.

Is your price a bulk price?

Hello, generally our quotation includes processing, assembly, and packaging.

Are you a factory or a middleman?

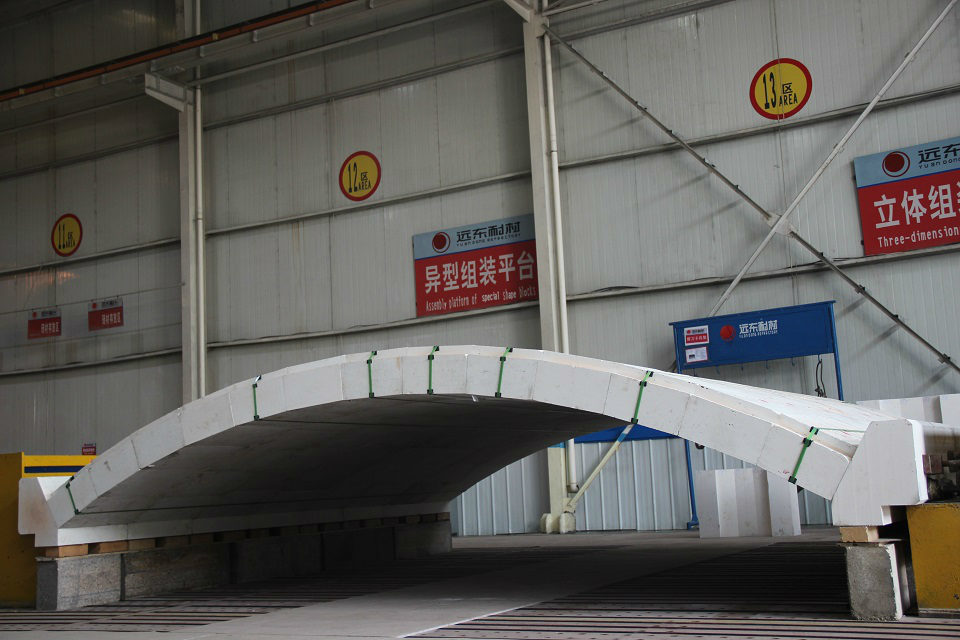

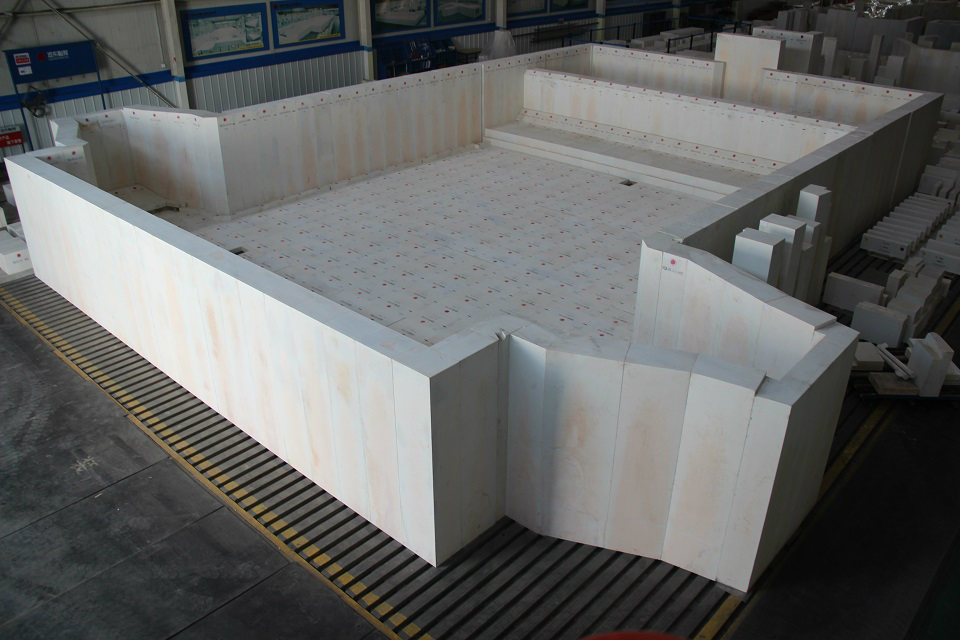

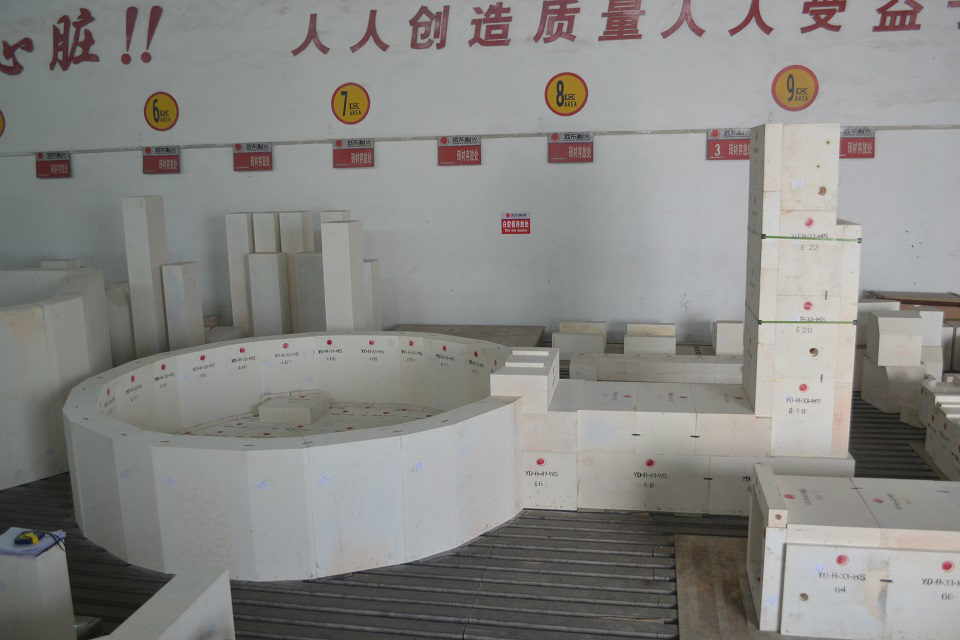

Hello, Far East Refractories is a refractory manufacturing company. Our users are spread all over the world. Asahi Glass, Almex, Swarovski, Xinyi Group, Qibin Group, Guangdong Huaxing, and others are our long-term partners, so you can purchase with confidence.

Customer Cases

Full oxygen combustion kiln roof charging

Float Glass Furnace Space

Belgian Horseshoe Flame Glass Furnace

Shanghai Glass Electric Fusion Kiln

Online Consultation

Please leave your relevant requirements, we will contact you as soon as possible