Special Management

After years of effort, Far East has established its unique management system

Far East-TPS

Since 2008, Far East has introduced the Japanese lean Toyota Production System (TPS). Under the guidance of Japanese experts Masaki Hashimoto, Koji Sano, and Masao Suzuki, it has gradually promoted 5S site management, TPM total productive maintenance, TQM total quality management, and PM policy management, establishing a systematic lean improvement innovation activity, ultimately creating the Far East-specific Far East-TPS (YPS):

5S Site Management

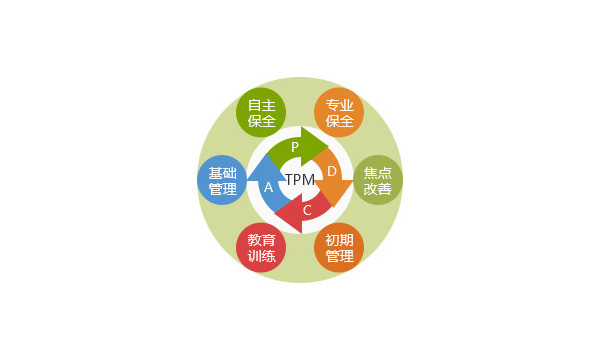

TPM Management, or "Total Productive Maintenance," originated in Japan in the 1970s. It is a production maintenance method involving all employees, focusing on "production maintenance" and "full participation." By establishing a production maintenance activity involving all system employees, equipment performance is optimized.

TPM Total Productive Maintenance Management

TPM Management, or "Total Productive Maintenance," originated in Japan in the 1970s. It is a production maintenance method involving all employees, focusing on "production maintenance" and "full participation." By establishing a production maintenance activity involving all system employees, equipment performance is optimized.

TQM Total Quality Management

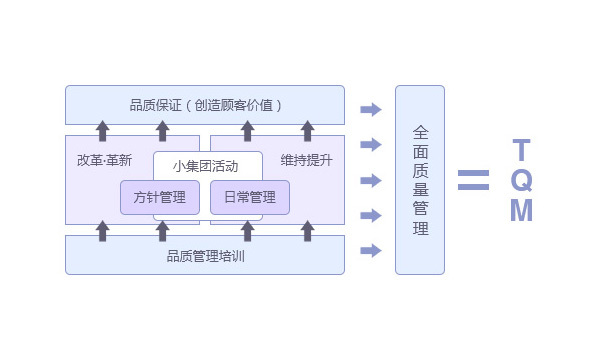

Total Quality Management (TQM) refers to an organization centered on quality, based on full participation, aiming for long-term success through customer satisfaction and benefits to all members of the organization and society. In TQM, the concept of quality is related to achieving all management objectives.

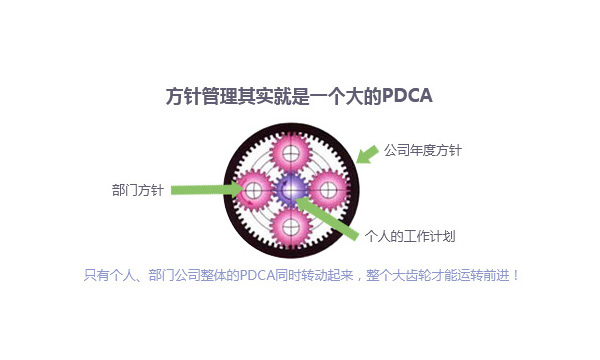

PM Policy Management

Total Quality Management (TQM) refers to an organization centered on quality, based on full participation, aiming for long-term success through customer satisfaction and benefits to all members of the organization and society. In TQM, the concept of quality is related to achieving all management objectives.

Far East-ERP

In 2014, based on refined activities, the company carried out PFK process analysis activities to optimize internal workflows, streamlining a pull production process suitable for company production needs, and formed its own information team. According to the optimized process, it developed the Far East-specific ERP system (referred to as Far East-ERP).